.jpeg)

.jpeg)

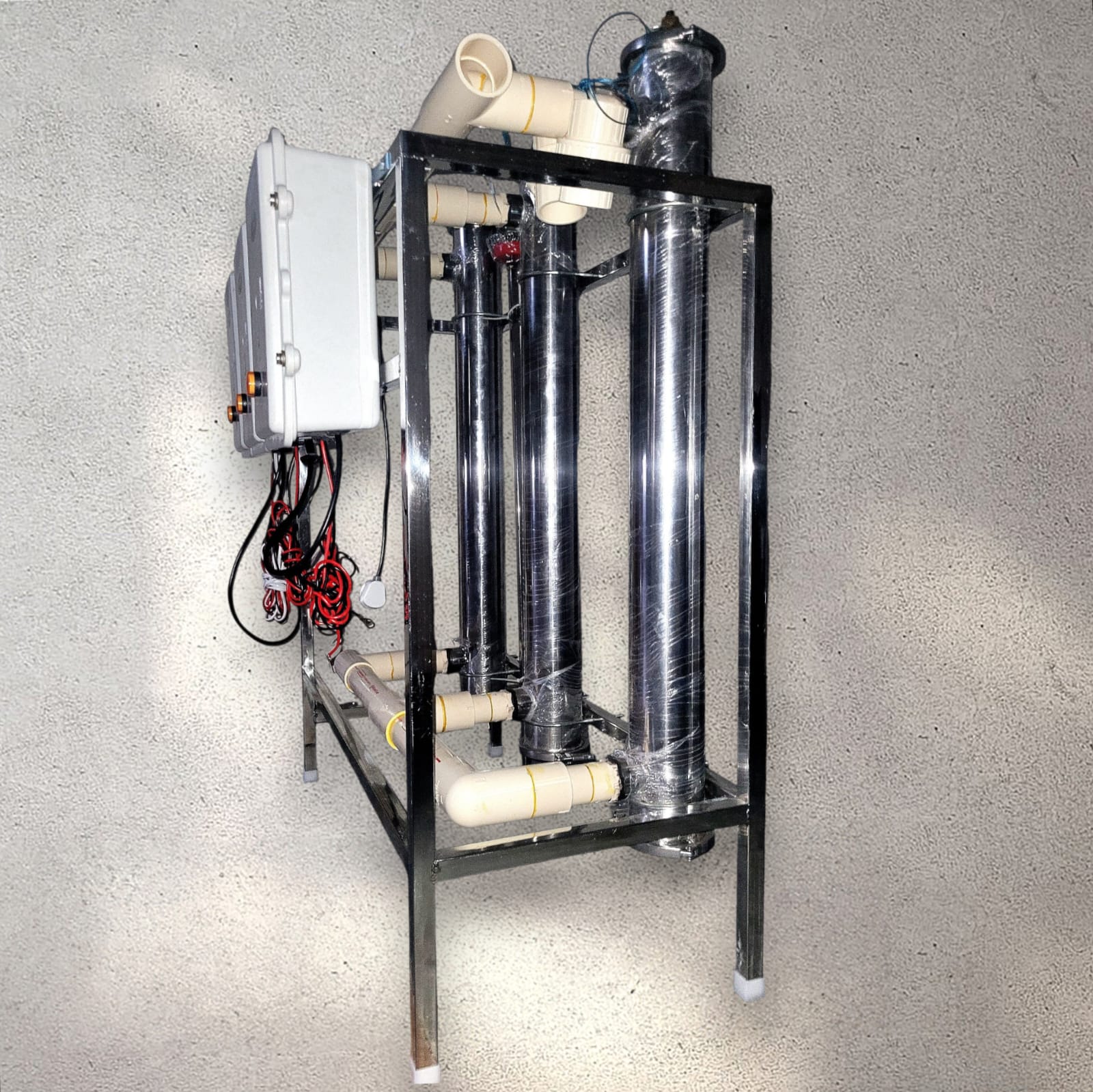

Electrolysis Lime Scale Removal System

ELECTROLYSIS LIME SCALE REMOVAL SYSTEM ELECTROCHEMICAL DE SCALING

Electrolysis Lime Scale Removal System in Andhra Pradesh. Watershed is one of the leading and well-known elsr system, ro plant system, industrial ro plant manufacturers, suppliers and exporters in Andhra Pradesh. Contact us and get the best prooducts.

The undesirable calcium and magnesium scale deposits on the surface of any materials in contact with water frequently lead to severe technical and economic consequences when the hard water is concentrated beyond the solubility limits of inverted solubility salts such as CaCO3 or MgCO3 etc in contact with a hot surface. Notably the deposition of a thick insulating scale layer probably causes pipe clogging in municipal and industrial water distribution systems reduces the heat transfer efficiency in the boilers and cooling towers and declines the water flux in wastewater treatment membrane systems etc.

The most widely utilized approach for preventing scale formation is using anti scalants to delay or prevent the mineral crystal nucleation owing to chelation dispersion lattice distortion and threshold effects.

The chemical reactions in softener are as follows

- CaHCO3 2 plus 2OH equals CaCO3 plus 2H2O plus CO3 2

- MgHCO3 2 plus 2OH equals MgOH 2 plus 2H2O plus CO3 2

Watershed India introduces a next generation hard water scale removal system ie Chemical Free Electrolysis Lime Scale Removal System ELSR a state of the art solution for water treatment scale removal device for domestic industrial and commercial application and RO feed pre treatment. ELSR effectively eliminates scale buildup controls corrosion and prevents bio contamination without the need for harsh chemicals. ELSR enhances the quality of water by eradicating scale formation. The water scale remover works on a principle of Electrolysis Technology.

The systems are usually designed as per the waters flow rate hardness and TDS.

Advantages of ELSR

- 100 percent savings on chemicals

- 60 to 70 percent savings on blow down water

- 10 to 50 percent savings on labor costs

- 20 to 30 percent of water savings

- It reduces the nitrate and fluoride from groundwater

- It helps in the reduction of salt stress on plants

Standard ELSR System comprises of the following

- SS Reaction Tube with Top and Bottom opening

- MOC of reaction tube SS 304

- Electrode Anode Titanium with MMO coating

- Max Feed Water TDS 2500 ppm

- Periodic cleaning time Approx 30 to 40 days

- Screen Filter SS Mesh screen filters 01 no at Inlet of ELSR

- Bag Filter 20 20 mcr 01 no at the outlet of ELSR

- Power Supply Switch Mode Power Supply SMPS 12V DC 30 Amps